S5 Electronics K-12M Tube Amp

Remember to completely unplug the unit

and let the capacitors discharge before you solder on it.

Caution: There is no

safety bleeder in the stock amp.

So you will want to build an insulated clip-on

discharge resistor to discharge the B+ caps.

Notice:

1. This project deals with lethal 115V

line voltage and higher voltages. You yourself must assume the responsibility

for your own safety and for those who come near your work.

2. If you modify the kit, you void your warranty

and neither S5 nor I will take responsibility for your changes to the amp.

3. This is an open notebook for sharing with

my friends. Use any information enclosed here at your own risk.

4. Don't contact me if the kit or mods don't

work. Learn to fix it.

5. This is based on the 2001 version of the

kit. If the kit changes, the mods may not work in your version.

I felt the need to build something. My big project

isn't going very fast (I'm avoiding the metal work.) I heard the K-12M

Tube Amp at the April Cactus Tube Dudes and thought I would play with it

a bit. I ended up buying the version with the tube cage. The metal work

was already done!

S5

Electronics Collects the Parts for the KIT and does the warrantee work.

Arizona

Hi Fi is the place I bought mine.

AudioExpress

Review of K-12M amp.

This 11MS8 amplifier was designed by George Fathauer

and has the following advertised specifications:

Input Impedance

= 100k ohms

Rated load

= 8 Watts into 8 ohms per channel.

Minimum Input for full output = 400 mV

Frequency Response

= 20 to 20,000 Hz

THD at 1 Watt

<1%

Performance Measurements I made:

On the stock amp I measured an output

impedance at 30 Hz of 4.5 ohms, 300 Hz of 5.1 ohms and at 3 kHz of 5.1

ohms.

At 3 kHz, I noticed that clipping just started

at 17V peak to peak into 8.45 ohms (resistive.) This is 9 watts peak output.

4.5W RMS.

The documentation for the kit is adequate, but minimal.

The web site instructions are a bit easier to read. However, I didn't exactly

follow the instructions to the letter.

Before I started the assembly, I clear

coated the bottom of the chassis with about 6 coats of clear spray paint

and very lightly wet sanded it in water with 600 grit after every coat

but the last coat so that it would look nicer. I also painted the black

top sandstone brown. I don't really like the sandstone brown, but I like

it slightly better than the stock black.

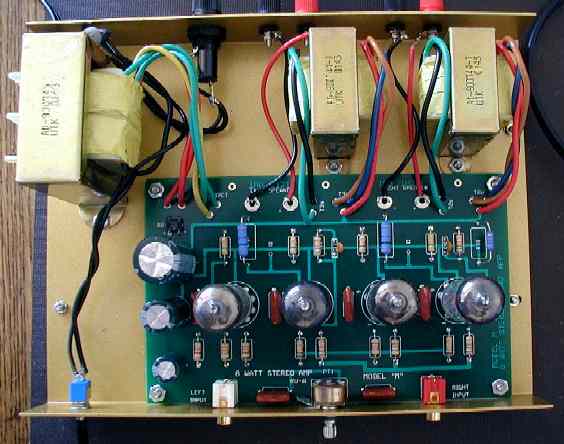

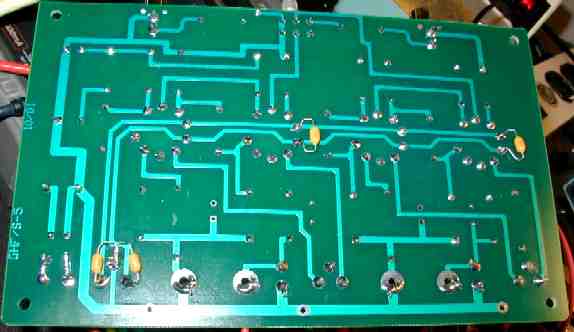

I ended up placing my output transformers

in the wrong way (as shown below) because I didn't have a picture to look

at. This ended up being a good thing because it made the board easier to

remove to do modification to it.

I checked the "polarity" of the 115V line transformer

primary with a signal generator and hooked it up so that the 115V lead

that gave the lowest chassis voltage went to 115V hot at the power switch.

I wired the 115V differently than the kit instructions.

I wired 115V hot to the fuse first and ran a wire to the power switch.

The spare transformer lead was hard wired to the 115V cold. I soldered

the 115V cold connection and put a wire nut over it. The wide plug is 115V

cold, ohm it out to find out which wire it is. I've been zapped by equipment

with the switch in the cold so I wanted both the switch and fuse in the

hot lead.

Note: The right most tube is tube 1.

Ohm readings made with unit unplugged, caps discharged,

tubes removed and volume pot all the way clockwise:

| Measurement point |

Tube 1 and 3 |

Tube 2 and 4 |

Black lead to |

| 1 |

Open |

Open |

Speaker Black |

| 2 |

86K |

Open |

Speaker Black |

| 3 |

1.46K |

47K |

Speaker Black |

| 4 |

<1 ohm |

<1 ohm |

Speaker Black |

| 5 |

<1 ohm |

<1 ohm |

Speaker Black |

| 6 |

Open |

Open |

Speaker Black |

| 7 |

Open |

Open |

Speaker Black |

| 8 |

298 |

298 |

Speaker Black |

| 9 |

470K |

470K |

Speaker Black |

|

|

|

|

| Test Change |

Tube 1 and 3 |

Tube 2 and 4 |

Red lead to |

| 1 |

153K |

50K |

+ of diode bridge |

| 6 |

75 ohm |

85 ohm |

+ of diode bridge |

| 7 |

468 ohm |

468 ohm |

+ of diode bridge |

|

|

|

|

The following should measure less than 1 ohm to

Speaker Black:

Case of power transformer

Case of each output transformer

Chassis of amp.

Speaker Red

Some Voltages. Be careful when you test the voltages.

Clip the ground of the DVM to speaker black and don't be touching anything

metal with your body when you probe around. Getting across the B+ or the

line voltage could be the last thing you do! Forever!

R8, R17 26V

R1, R9 1.29V

R3, R13 65V

R4, R21 197V one side, 132V

the other side.

Initial power up:

My kit oscillated at 100 kHz at first

power up so I went to the web site and saw a note about a ground lug on

the volume pot. Sure enough, there was no continuity from the speaker black

terminal to the chassis because of the paint. I put an internal tooth lock

washer between the ground lug and chassis and the oscillation stopped.

After that, I put internal tooth lock washers under the both the nut and

screw on each of the transformer mounts that face the circuit board.

Now I went to listen. The sound was good for a

$225 tube amp. There was some hum and buzz that I found annoying with my

100 dB/W speakers so I went out to try to fix that.

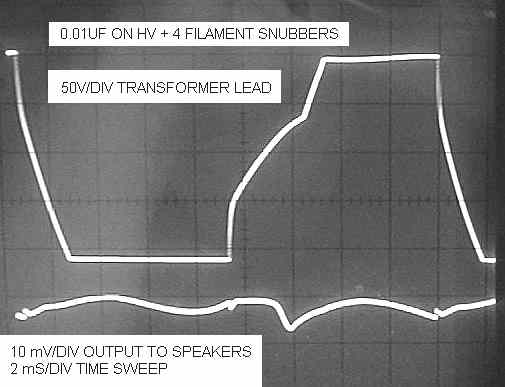

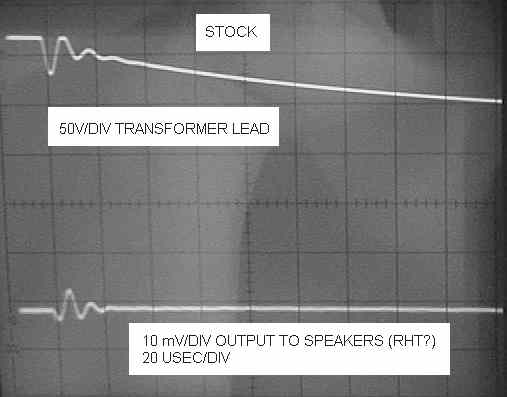

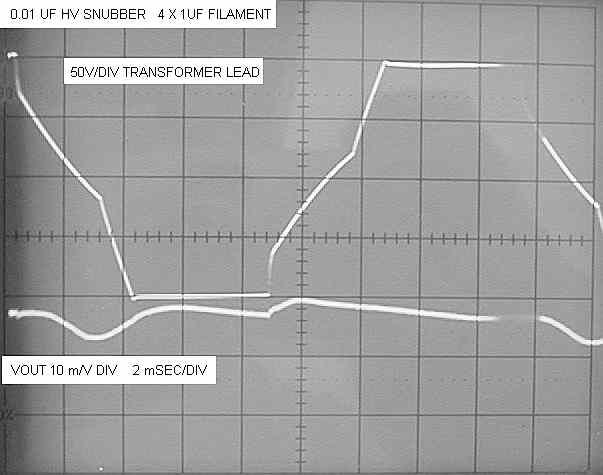

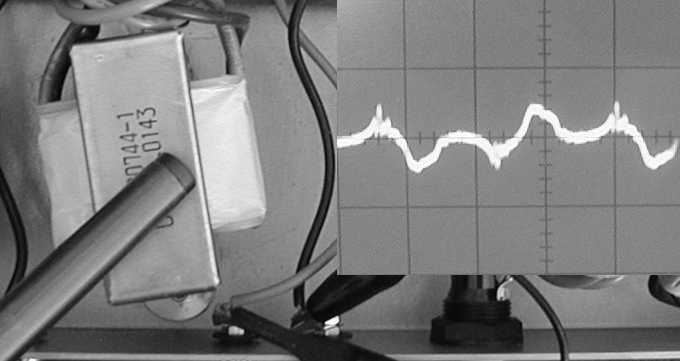

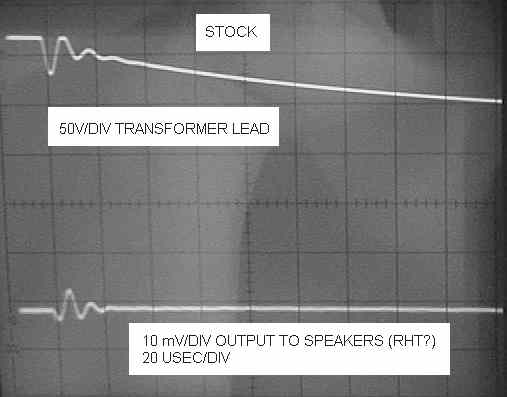

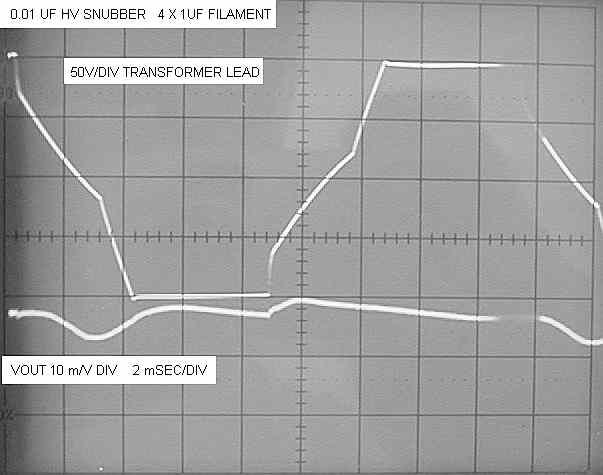

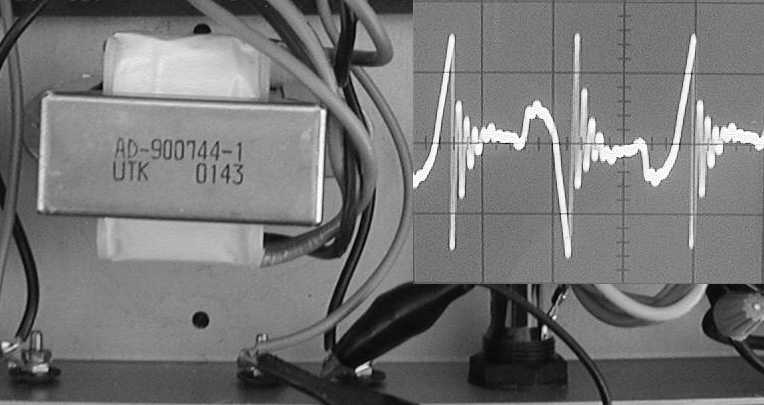

Rectifier Noise

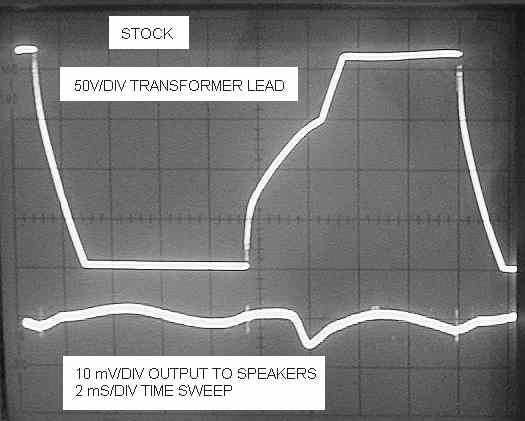

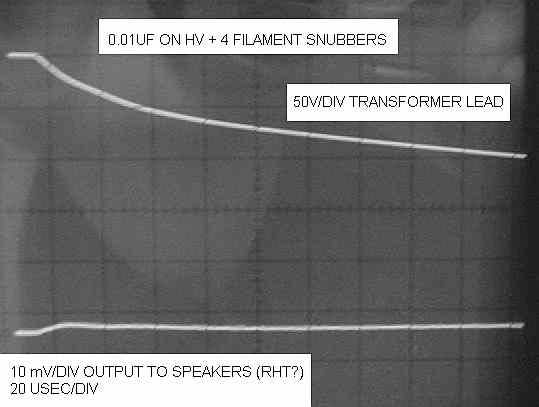

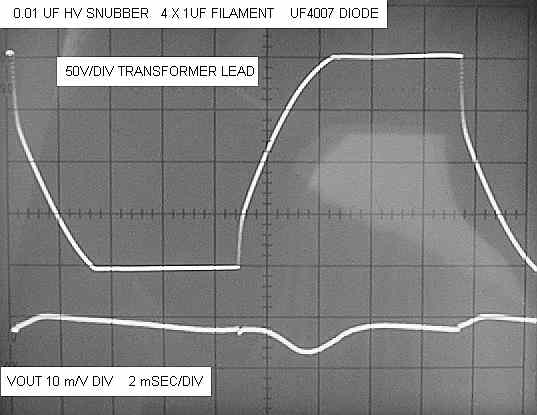

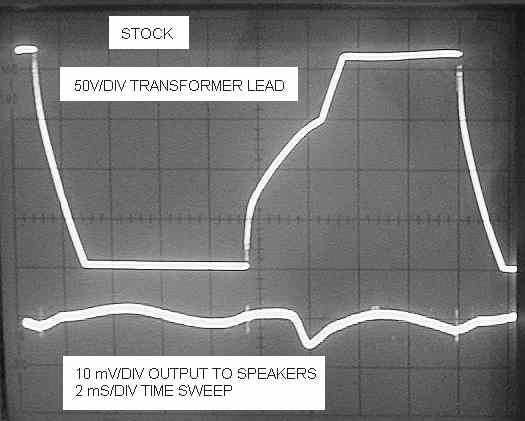

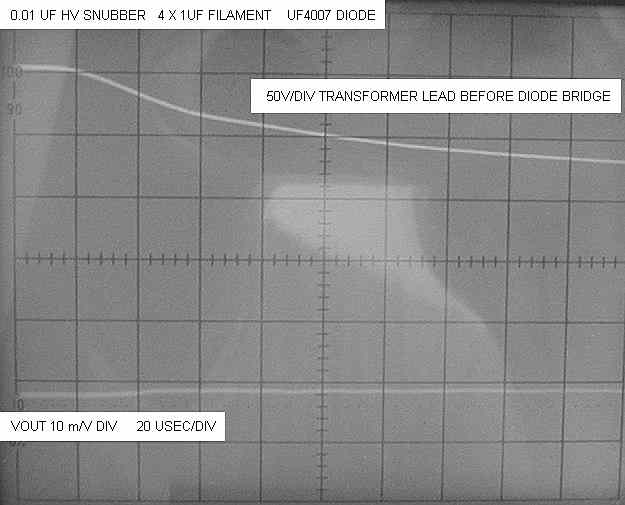

The stock amp has about 10 mV pp ripple with little

diode recovery spikes on the output. You can see the spikes every time

the top trace stops being flat and changes direction. Because the output

noise has spikes and sharp points, it will be very broad band noise. The

spikes show up as tweeter noise and the jagged edges as midrange noise.

The output noise also has "wiggles" in it that do not show up in the photo.

This usually is a "hissy" type of noise.

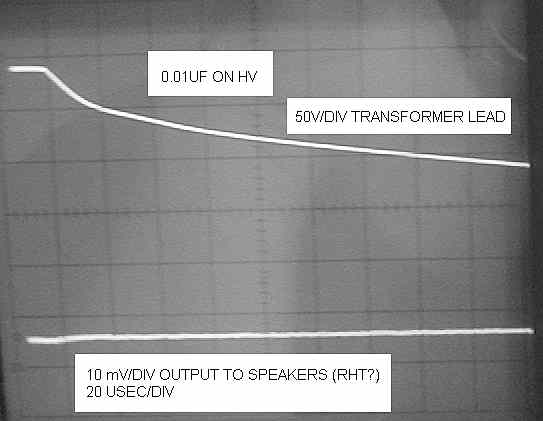

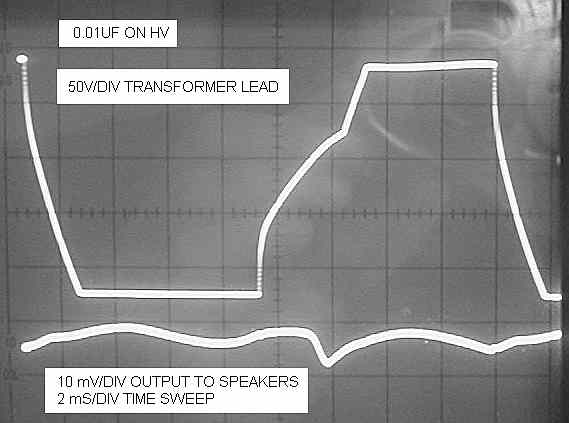

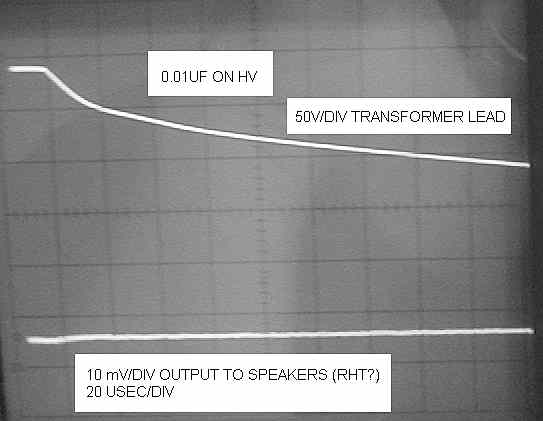

With a 0.01 uF 2 kV Radio Shack ceramic across

the HV transformer leads, the narrow spike on the output goes away, but

the low frequency stuff stays.

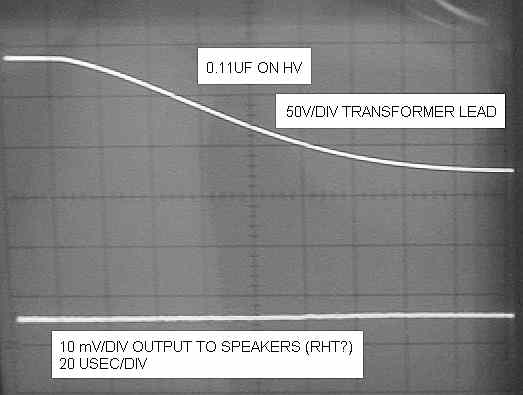

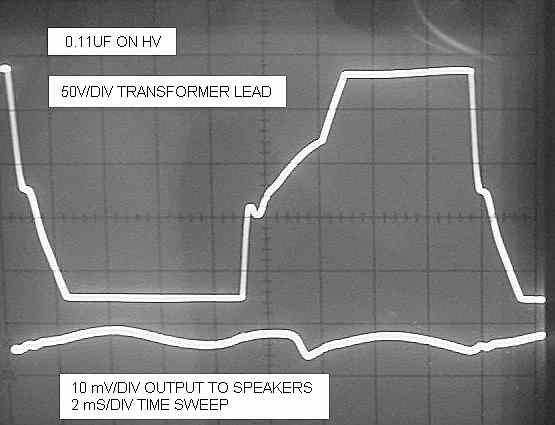

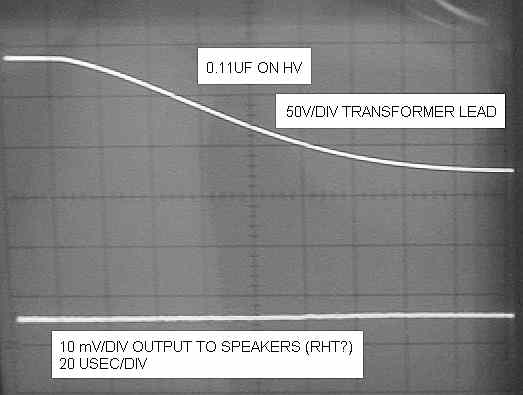

With a 0.1 uF 400V film across the 0.01 uF. The

output looks like it has a little less low frequency noise, but overall

things look a little worse so I left the 0.01 uF in. I'll go back and tweak

it up better another day.

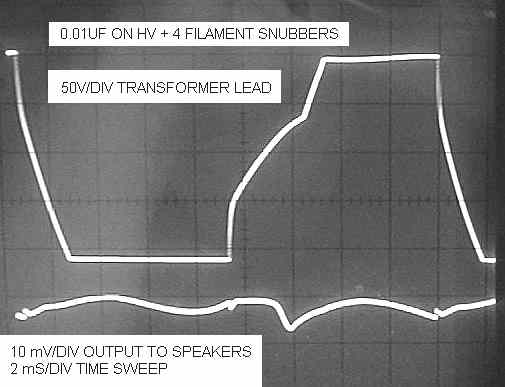

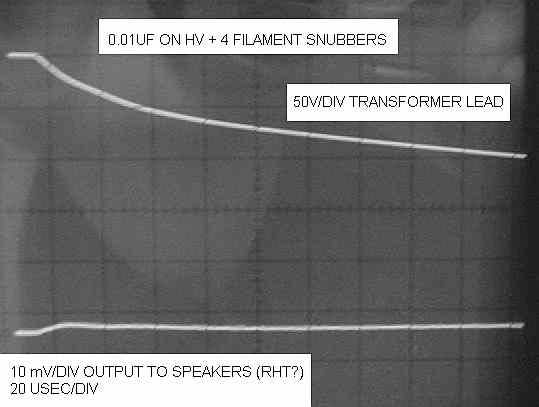

It is not apparent in the scope pictures, but the

output trace is still "fuzzy" with high frequency noise. So I added four

1 uF caps as filament snubbers. This made the trace much thinner, but I

got a little bump back in the output noise from the diode recovery. This

output noise from the circuit I decided to go forward with.

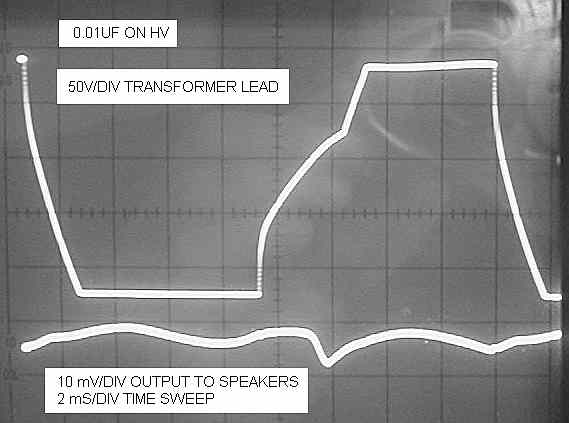

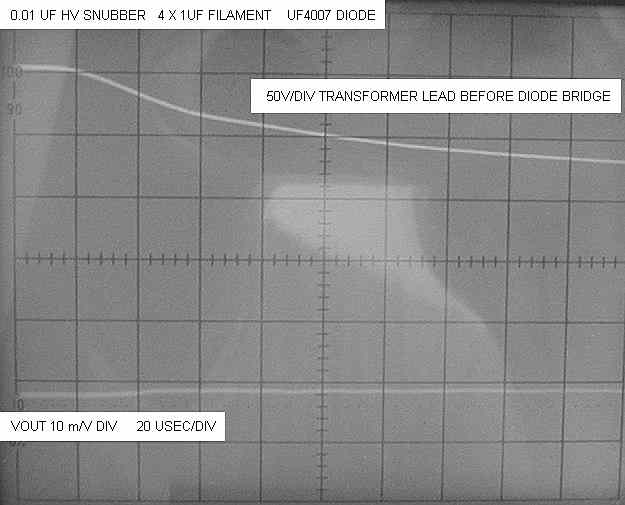

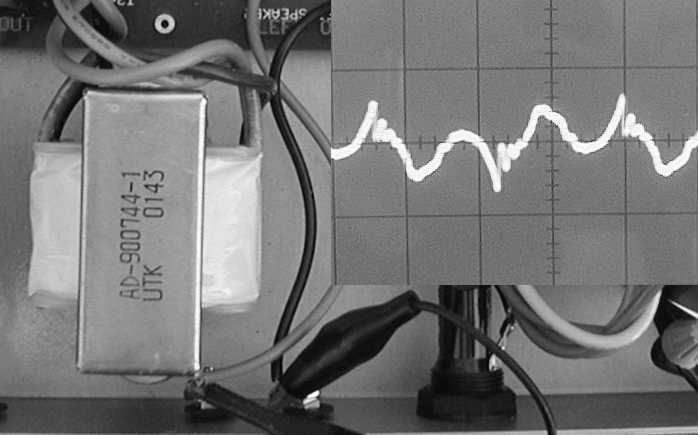

Here are the close-ups of the ringing. That's almost

50V pp on the transformer lead.

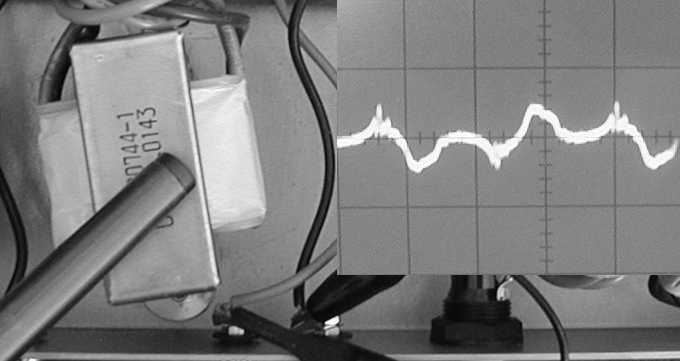

The 0.01 uF really reduces the ringing to almost

nothing.

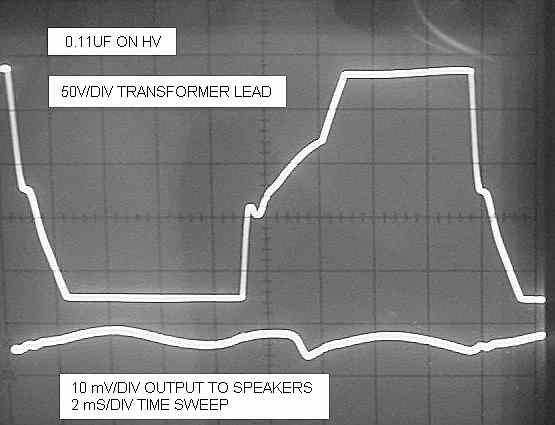

The 0.11 uF reduces the ringing even further, but

the 2 msec/ div waveform showed a jagged response that made me stay with

the 0.01 uF. To make the decision easier, the 0.1 uF was much harder to

fit in the circuit, the 0.01 uF was fairly easy to fit.

This is what I settled for on the final version.

The filament snubbers brought back a little bump the output noise. However,

the reduction in trace noise on the output still does not show up on the

scope photos. The trace with the filament snubbers is much thinner.

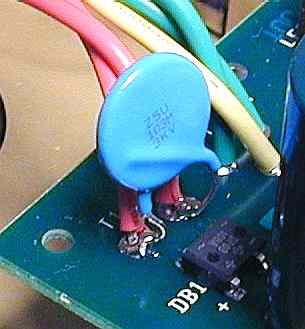

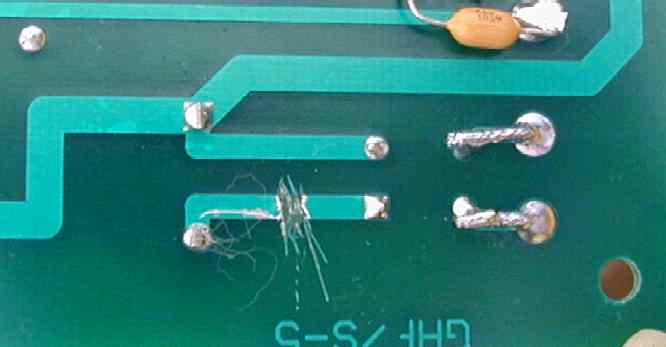

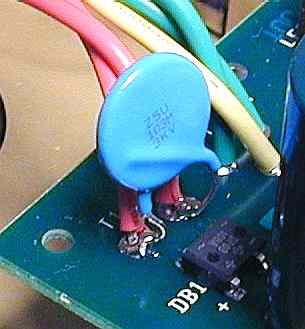

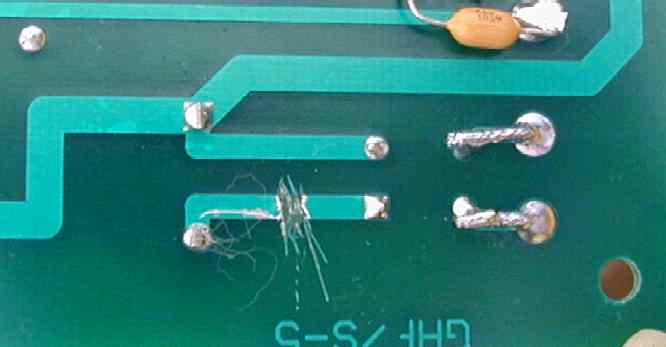

Here is what the 0.01 uF mod look like:

Notice that I made the solder joint as far from

the mounting screw as possible. I pulled the lead insulation up with a

needle nose before making the solder joint. After cleaning, I ohmed the

leads of the cap to the leads of DB1 to verify continuity. Caution: Too

much soldering heat here can ruin your output transformer, transformer

leads and ceramic cap. Hint: Put a paper weight on the transformer leads

to keep them out of the way while I was soldering.

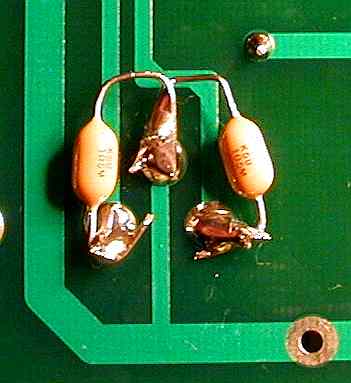

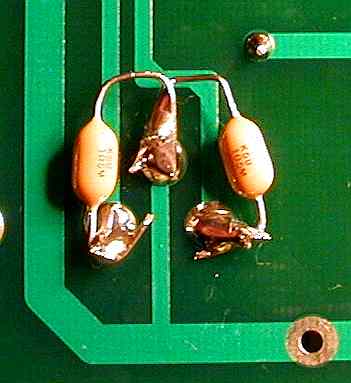

The filament snubber capacitors are 1 uF Z5U 50V

axial caps from Mouser (the bag they are in said 80-C430C105M5U). They

are mounted flush to the printed wiring board (PWB) and the soldering time

was kept short. On the right picture you can see a cotton thread from the

Q-Tip I used to clean the flux off after soldering. 1 uF caps on all 4

tube filaments may be a bit better, but I'm starting to get low on my supply

of 1 uF ceramics. Next time I order these caps, I'm buying a larger lot.

These solder joints look better in real life than what the photos show.

Here is the big picture.

Listening to the amp afterward showed that the

tweeter noise was 100% gone and there was still some low midrange/bass

buzz/hum noise coming out. The sound was much more pleasant with the snubbers

installed. The sound stage had a bit more depth than before. Occasionally

there I could hear some brightness that I'd like to track down and fix.

The HV snubber also seems to have reduced, but

not eliminated, the pop you get when the power is turned off.

Update: Originally, only two of the tubes have

snubbers across them. When I had my amp open for more B+ capacitor mods,

I added 1 uFs across the remaining two tubes.

HV Snubber Version 2

C-RC

Last update 20-Feb-05

I found a slightly better snubber to use:

First we keep the 0.01 uF across the HV secondary. This cap

needs to be a 2 to 3 kV ceramic or a 400 to 600V film. The ceramic needs

to be higher voltage to keep it from cooking. The films don't get near

as hot.

Next, on the tube side of the 0.01 uF, we add a 0.1 uF (400V or 630V

film). From the other side of the 0.01 uF, we add a 620 ohm 1/4 resistor

to the free leg of the 0.1 uF.

Last, after ohming for shorts, put a pea sized spot of silicon based

glue to hold the capacitors in place. I glued my 0.1 uF to C8, the B+ aluminum.

Tube Filament Inrush Balancing

Last update 12-Feb-05

I have heard that some people can see the tube

filaments come up from left to right on a cold amp (power cord is on the

left.) I was also told that the filament in the tube closest to the power

transformer fails most often at power up. This happens because the resistance

of the circuit card traces limit the inrush to the last tubes, but the

first tube doesn't get this benefit.

We can reduce this issue.

Run a #22 wire from the first tube's pin 4 (filament)

to the last tube's pin 4. Then run a separate #22 wire from the first tube's

pin 5 (filament) to the last tube's pin 5 to beef up the filament traces.

Lightly twist these wires (about 2 turns between each tube). Use one color

wire for 4 and a different color wire for 5. IF YOU DO THIS WRONG AND

GET 4 HOOKED TO 5, YOU'LL COOK YOUR POWER TRANSFORMER AND/ OR THE PWB!

Triple check your wiring for shorts and that pin 4 goes only to pin 4 etc.

If you really want to do this right, when running

the wire, cut back the insulation at each tube and make a solder joint

at each filament. For me, that's just too much work.

Adding an Ultra Fast Diode in Series With

the Diode Bridge.

A standard recovery diode can remain a short for

several microseconds after the transformer voltage drops below the B+ capacitor.

During this time current flows the wrong way in the diode until the diode

"recovers" its ability to block voltage. When it does recover, the parasitics

of the transformer tend to ring and radiate noise because of the reverse

current flow. By changing the diode to an ultrafast diode, we can sometimes

cut the unwanted noise energy a factor of 100 or more.

The K-12M uses a full wave bridge to change the

AC from the transformer into the B+ voltage. If we put just one ultrafast

diode between the standard full wave bridge and the B+ capacitor, we get

the full benefits of ultrafast rectification. We only have to buy one ultrafast

diode to do this. It wouldn't be too hard to replace the entire bridge

with ultrafast diodes, but I want to prove a point here and show again

only one diode is needed.

First you have to make an 1/8 cut in the B+ trace

between the first cap and the diode bridge. I like to make a few cuts with

the Xacto Knife and then put some solder on the area to be lifted out.

The heat from the solder makes the trace come up easier. Before installing

the diode, clean any flux and metal off the cut. Before you go much further,

chase down all the metal flakes you just made cutting the trace and keep

them out of the transformer and other circuitry.

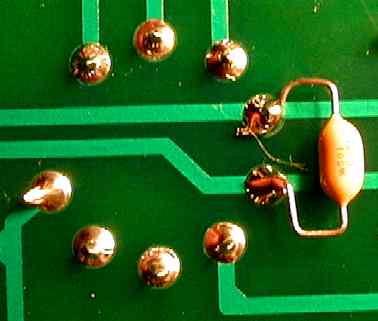

This isn't a first class job, but it works. It

ohmed open and I didn't cut my fingers or any other parts! When you wet

the cut with acetone/ alcohol, you can see that there is no metal between

the two traces. The white specs you see in the cut are scratches in the

fiberglass, not metal particles.

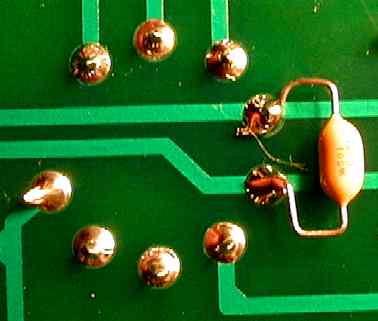

Next lay a UF1007 (or UF4007) across the cut as

shown and clean all the new flux off. The diode must be flush against the

PWB.

First the BEFORE Picture. Notice the jagged waveform

on the 50V transformer lead. The jagged slopes on the transformer windings

easily couple energy into adjacent circuits.

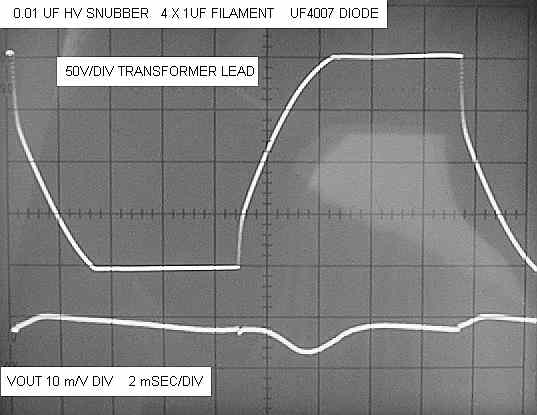

With the ultra fast diode installed, notice how

smooth the HV winding is. Smooth edges generally couple less noise.

Here is the close-up of the diode recovery. The

bump on the output is much lower because the ultra fast diode does not

dump as much energy into the transformer as the standard diode does.

The listening test was a positive experience. The

tweeter was still dead silent. The midrange noise was even lower than before.

By request:

I was requested how to do this mod without cutting

the traces. To do that, you have to replace the diode bridge with four

individual UF4007's. They are wired like this:

Note: I still think having one ultrafast diode in

series with the bridge is just as good as putting in four new ultrafast

diodes. The question boils down to would you rather unsolder the diode

bridge and add 4 diodes or cut one trace and add one diode. If you decide

to unsolder the bridge, I recommend using a very sharp cutter to cut the

leads of the bridge off by the body of the bridge before you unsolder the

leads from the PWB.

Yes, You Still Need Snubbers with UltraFast

Diodes.

Last update 12-Jul-05

Reverse recovery spikes are only one source of noise

and ringing on transformer windings.

Other sources include:

1. Dumping of the energy stored in leakage

inductance at end of charging of the B+ caps in cap input supplies.

2. Dumping of the energy stored in leakage inductance

at zero voltage crossing of the diode bridge in choke input filters with

chokes equal to or bigger than the critical inductance.

3. Dumping of the energy stored in parasitic capacitance

at the zero current crossing of the diode bridge in choke input filters

with chokes less than the critical inductance.

4. Non-sinusoidal current flow in one transformer

winding causing voltage distortion in other winding.

5. Line noise ringing the LC tank made from the

leakage inductance and the capacitance (parasitic capacitance and purposely

added capacitance) on the transformer windings.

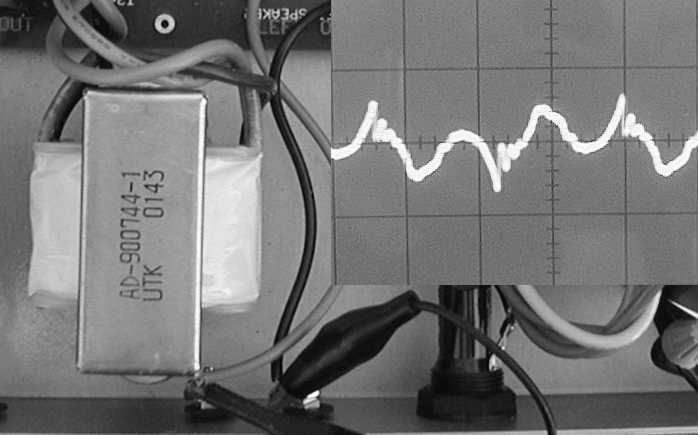

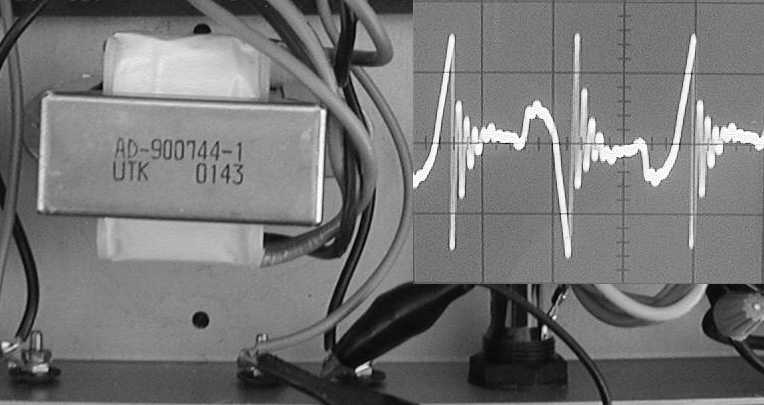

Finding The Best Transformer Rotation

Last update 12-Feb-05

I pulled all four tubes from the amp and placed

a 4.7K dummy load on the B+ so the power transformer was conducting current.

I then rotated the transformer to find the lowest coupling with no load

on the output transformer. These pictures were taken with the 0.01 uF HV

snubber installed.

This is what the stock left transformer rotation

looked like. (5 mV/div 5 msec/div)

I rotated the top screw hole so that the edge of

the mounting flange was just touching the edge of the existing mounting

hole. This resulted in the best mounting position.

I then continued to rotate the transformer until

it was about 90 degrees from the original mounting. This is about the worst

mounting location. However, this is the easiest mounting location if we

want to install bigger speaker terminals posts.

I repeated these tests on the right transformer,

and it was best at the exact same angle. The flange that on the volume

control side is angled away from the power transformer until it just touches

the edge of the existing hole.

When I remounted the output transformers, I put

1/2L Flat 25/32" OD Faucet Washers (Neoprene?) under each flange to offer

some vibration damping. This suggestion came with a friend who is into

vibration control in audio equipment. One of the tricks using damping washers

is to tighten the screw so it is just firm, not tight. Then rely on internal

tooth lock washers under the screw and nut to keep the screw and nut from

loosening.

With the Neoprene washers installed, the transformers

and chassis sounded better damped when tapped than with out the washers

under them. Unfortunately, I'm not sure if I heard a big change in the

sound. However, this mod is cheap to do and probably does help when listened

to in a better listening room than my office.

B+ Beef

Last update 12-Feb-05

I was looking at the K12M's B+ and thought it needed

a bit more beef both on the screen supply and the supply that feeds the

driver tubes.

The screen supply (C9, 100u) is much more

sensitive to noise than the B+ itself (C8, 220u) so it needs to be stiff

(low impedance).

The supply that feeds the driver tubes (C5, 22u)

also needs to be low impedance. This will reduce crosstalk between channels

and reduce the sound of the electrolytic in the circuit.

I've got 5 caps and two amps. Since I'm replacing

two of the B+ caps, I'm also planning to replace the third cap, the plate

supply B+ on my second amp.

The cap that looks like the best compromise of being

able to fit and work right is the Nichicon UVR2E331MRD 330 uF 250V cap

Digikey part number 493-1199-ND. These caps have a measured 10 kHz ESR

of 0.137 ohms.

Note: A friend of mine has installed these caps

in his amps in all 3 positions and reported that he liked the results.

I've got my caps now. I just put them in the C5

and C9 position. I had to bend the both leads to get them to fit in the

existing holes. I used a thick bead of Silicon Adhesive on the bottom of

the caps to the PWB to keep the caps from wiggling too much. This

mod is worth it. There is a noticeable increase in focus and solidity to

the sound stage as the volume changes that wasn't there before.

When bending the leads, they get bent

into a Z. Hold a needle nose pliers on the lead flush against the cap's

body to make the first bend. Place the cap so that it almost hangs over

the edge of the PWB.

Halo Tube Dampers

Last update 6-Feb-05

Hal-O

Tube Dampers These helped. I tried these so long ago, I

can't remember the exact differences other than I like it. They've helped

on 12AU7s, 12AT7s these 11MS8 tubes. I didn't hear much on my good 2A3s.

I haven't tried them on my microphonic 2A3s.

CCS FOR DIFFERENTIAL OUTPUT TUBES

Last update 19-Feb-05

The 300 ohm 3W cathode resistors R8 and R17 are replaced with a simple

constant current source. Because the tubes were running so hot, I dropped

the current a bit below the stock bias point. The stock bias was 86 mA

(~8.2W per plate). I set the CCS current to 75 mA (~6.5W per plate). This

CCS has an LED in it just for show, it can be removed to simplify the circuit.

If the LED is removed, keep R5 and R6 in the circuit to help the FET to

run cooler. It takes about 5 to 10 seconds of power being applied before

the LED lights up.

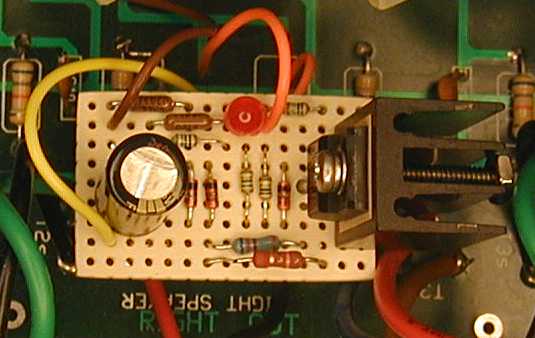

I used parts from several old Digikey orders to build this. Here's the

parts list for one channel:

Radio Shack

1 1.0" by 1.5" perf board

1 Radio Shack RED LED

(D4)

ACE Hardware

1 #4 1 inch screw, flat, split and nut.

1 1/2 inch nylon standoff (This is glued under the

perfboard to the PWB to hole the mod in place.)

1 Silicon Adhesive.

Digikey

1 HS301-ND

(Heatsink)

1 BER113-ND

(K10 thermal Pad)

3 1N5234DO35MSCT-ND (D1, D2, D3)

1 IRFIBF20G-ND

(Q1)

2 P20.0CACT-ND (R5,

R6)

1 BC130W-1CT-ND (R1) <-- 1 Watt (Or

use 110 ohm 1W and not install R8)

2 P110CACT-ND

(R4, R7 or 100 ohm)

2 P140KCACT-ND (R2, R3)

I used a different part for this in the picture below,

any 140K 1/4 is good enough.

1 493-1554-ND

(C1)

Fry's Electronics

1 R8 / Rtrim (I used an NTE 620 ohm 1/4W

film ), leave R8 out Or use a Digikey P620CACT-ND

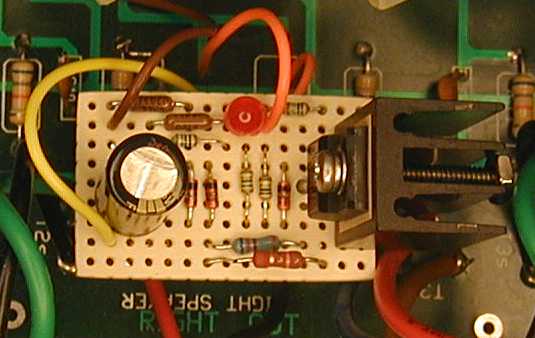

Here's the part's placement and wiring guide part side view.

Here's a close up of the finished CCS. The 130 ohm 1W resistor is stood

1/4 inch above the perf board to keep it from browning the board over time.

The heatsink was mounted by drilling the holes in the perf board open to

the holes a bit and pushing the perf board onto the heatsink pins with

a large flat bladed screwdriver. The holes for the FET lead were enlarge

a bit too.

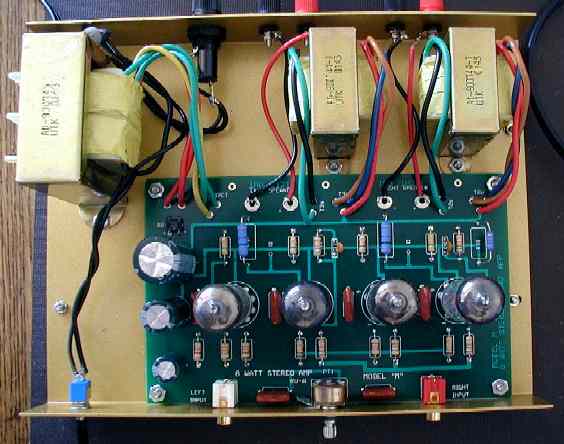

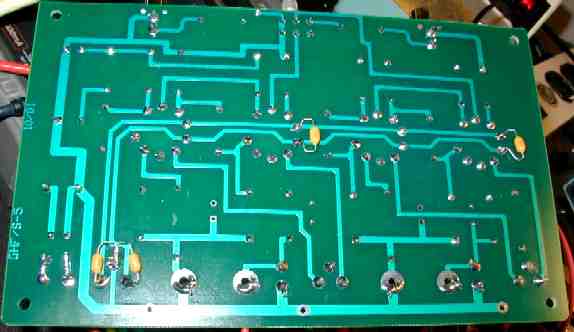

Here's the amp with the Hal-O's, rotated output transformers, B+_Beef,

C-RC snubber and CCS'd cathodes on the output tubes.

The CCS on the output tubes improved the smoothness of the sound.

CCS FOR DIFFERENTIAL OUTPUT TUBES

Last update 15-Aug-05

One set of tubes in my amp weren't matched very well so I manually balanced

the bias by trimming a set of grid bias resistors. I have a better way

of doing the balance and it is shown below. I haven't made my version of

this circuit, but I've shared it with a few people who wanted to try it.

Notice that R2 and R3 have dropped in value to support the bias current

for R10 and R11.

Setting the bias point Version 1

To set the bias point, with the power off, the capacitors discharged

and the unit unplugged, measure the ohms from the plate of each tube to

the center tap of the output transformer. Write these numbers down. With

the power off, clip the red lead of the DVM to the CT of the output transformer.

Let the tubes warm up and then with the black lead, carefully measure the

voltage from the center tap to the plate of each tube at the same point

you measured the resistance. Turn the power off and wait for the caps to

bleed down before moving the leads to the next output transformer.

From this calculate the the bias current.

I_BIAS = V_LEFT / R_LEFT + V_RIGHT / R_RIGHT

Then calculate the voltage you need read in order to trim the pot.

V_LEFT_Balanced = R_LEFT * I_BIAS/2

Setting the bias point Version 2

To set the bias point, with the power off, the capacitors discharged

and the unit unplugged, measure the ohms from the plate of each tube to

the center tap of the output transformer. Now in series with the winding

that had the lowest ohms, add a 1W (2W or 5W) resistor. Double check your

ohm measurements after it is installed. You want to get the resistances

measured from the plate to the CT to be less than 5% (2% goal.)

Now clip the DVM between the plates of the two tubes, turn the power

on, let the tubes warm up and adjust the balance pot for zero volts dc

between the plates of the two tubes. Turn the power off and wait for the

caps to bleed down before moving the leads to the next output transformer.

Ideas for future mods:

1. Add a safety bleeder on B+ (390K

1/2W) (Done with bias resistor in CCS.)

2. Replace C1 and C4 with a 100K metal film and

convert the volume control to shunt mode. This could go in series with

C1 and C4 if you want to keep the DC blocking.

3. Upgrade the coupling caps to polypropylene.

4. Possibly add a grid stop on the output tubes

(On the trail for a brightness fix.)

5. Possible add an RC zobel across the primary

(On the trail for a brightness fix.) Tried it, it wasn't worth it.

6. Add a single ultrafast diode between the

diode bridge and the first cap. You don't have to replace the entire

bridge! One diode here is good enough. (Lower output noise.) - DONE

Worked great

7. Use a CCS for R10 and R2 in the first gain

stage. (It did wonders all the other times I C4S's something.)

8. CCS the output differential pair. - DONE

Worked great

9. See how far I can drop the output impedance

and still have a stable amp. (I got to play.)

10. Add another B+ filtering stage for the

output tube or increase the B+ capacitor values. (Lower output noise,

tighter bass.) - Done Bigger caps are RECOMMENDED

11. PDMPS the driver stages. (Chasing a wider

sound stage.)

12. Neoprene bushings under between the power

transformer and case (The line transformer's case should go to safety ground.)

- Done. I used DANCO 1/2L Flat Faucet Washers 25/32" O.D. Stem Repair

P/N 88578 (Ace Hardware?) Looked cool, but didn't help the sound

a lot.

13. Raise the filament voltages about 50V above

ground to try to reduce hum further.

14. Add balance adjust for output stage bias current.

(Done with discrete resistors, I have plans to put in a bias balance

(bass balance pot) in the near future. One pair of tubes were not matched

very well, the other was dead on matched..)

15. Beef up copper in filament traces. (Done.

The tube seem to share the inrush current nicely.)

First release 20 Apr 2003 AM, Last

update 15-Aug-05

This web page may not be copied nor

reprinted in any form.